The 7th WCIFIT | Technology Empowers All Industries: A Close Look at the 2025 WCIFIT Inspection & Testing Zone

On May 22, the Inspection & Testing Zone at the 7th Western China International Fair for Investment and Trade (WCIFIT) was packed with visitors. Twelve top-tier institutions showcased "black-tech" solutions that empower every sector, blending hard-core science with everyday services and leaving the crowd amazed.

Tech safeguard: firming the industrial upgrade foundation

Inside the exhibition zone, a high-precision atomic clock stood beside a hotpot broth test bench; a 25 MW wind-turbine drivetrain model was displayed next to an elevator safety system - both "heavy-duty breakthroughs" and "daily-life guardianship" are on view. A real-time "Inspection & Testing Service Map" flashed key figures on a giant screen: a RMB59.8 billion industrial cluster, 19 national quality-inspection centers and 54 public-service platforms, sketching the rise of a testing powerhouse in Western China.

East of the exhibition zone, the TA(CMQ) atomic time-scale device of the Chongqing Institute of Metrology and Quality Inspection drew crowds. TA(CMQ) offers independent, high-precision time-keeping, filling a critical gap for Chongqing.

"Micro-nano industrial CT and SEM-EDS systems restore the nanoscale world, enabling western Chinese enterprises to solve non-destructive precision-testing problems at home," explained an engineer during a live demonstration, prompting an immediate service reservation via QR code scan by a representative from a new materials company.

Nearby, China Automotive Engineering Research Institute (CAERI)'s 25 MW wind-drivetrain test bench stood tall. Its self-developed spindle-tilt system accurately replicates nine global wind-field conditions, prompting on-site collaboration discussions with companies like Goldwind.

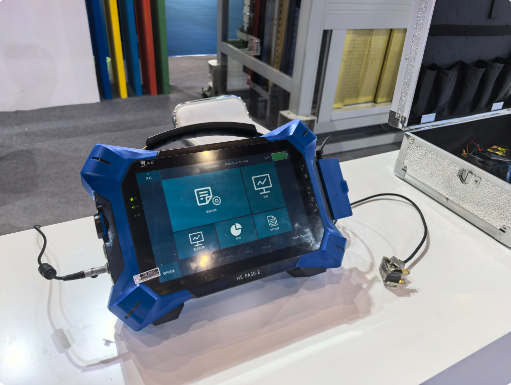

Is your software truly "hardcore"? The Software Testing Laboratory of Chongqing Institute of Quality & Standardization presented its "performance efficiency testing marvel", capable of conducting 500-user concurrent impact tests and 7×24-hour extreme stress tests. Functioning like a "software diagnostic doctor," this tool precisely identifies system issues such as lagging, crashes, and overload symptoms. The institute is currently developing a first-class software evaluation center for the upper Yangtze River region to ensure all software can withstand massive user traffic.

At the "Rapid Food-Safety Screening" zone, the Chongqing Institute of Food and Drug Control drew constant attention with two self-developed innovations. The Food-Utensil Cleanliness Analyzer delivers a precise surface-hygiene verdict in just one minute - an order-of-magnitude leap over traditional methods - while the Multi-parameter Rapid Test Kit uses a single sample prep to screen 16 pesticide residues in fruit and vegetables simultaneously. These products have been widely adopted in food safety monitoring systems across the region.

Safeguarding livelihoods: from food safety to life protection

"Authenticity confirmed within 3 seconds." At the exhibition zone of the Chongqing Institute of Food and Drug Control, visitors formed a steady queue. Resident Ms Li placed a package of hotpot broth into a portable infrared spectrometer; within seconds, a characteristic "fingerprint" spectrum appeared on the adjacent display.

"Illegal additives are rendered immediately detectable - technology is safeguarding the authentic flavour of Chongqing," an institute expert stated. Adjacent to this station, the seasoning-authentication section drew further exclamations: microscopic images of Sichuan-pepper cell structures were compared against certified reference atlases, enabling instantaneous differentiation between genuine and counterfeit products.

To address public concern over school-meal safety, an ATP fluorescence detector became a focal point for parents. After swabbing a child's lunch tray, a reading below 30 RLU was required to confirm cleanliness. "Previously we relied on visual inspection; now we rely on data," remarked Grandmother Zhang, who was accompanying her grandson.

The Chongqing Medical Device Quality Inspection Center presented critical technologies for evaluating mask filtration efficiency and the water-penetration resistance of protective clothing. The center's electromagnetic-compatibility laboratory - equipped with internationally recognized 3 m, 5 m and 10 m anechoic chambers and high-frequency test systems - now covers medical devices and household appliances in both indoor and outdoor environments, while offering design-verification services to support enterprise technology upgrades.

Chongqing Anbiao Testing & Research Institute Co., Ltd. also exhibited inspection technologies for coal-mine safety and ventilation equipment, generating significant interest among attendees.

Building tomorrow: the "Innovation Leap" from laboratory to industry

Amidst the rhythmic pulse of the "hydrogen energy heart," CAERI showcased a comprehensive hydrogen technology solution spanning storage, transportation, and application, with key components including hydrogen circulation pumps, hydrogen pressure reducers, flow control valve assemblies, and hydrogen injectors - products developed under the State-Owned Assets Supervision and Administration Commission's "1025" initiative and national key R&D programs, which have undergone rigorous testing and achieved breakthroughs in high durability, safety, and other critical technical metrics.

At the adjacent booth, a futuristic scene unfolded as the "digital twin" system for power batteries demonstrated its capabilities, leveraging real-world vehicle data accumulated over millions of kilometers to achieve a 97% accuracy rate in capacity detection.

Meanwhile, a dramatic moment captivated the special equipment safety demonstration area: as an elevator model plunged abruptly, the Chongqing Special Equipment Inspection and Research Institute's AEB protection system responded instantaneously, with rail brakes halting the cabin precisely mid-descent.

"This system already safeguards 2,000 elevators in Chongqing with an error margin under 5 centimeters," revealed a technician, noting that the extreme cold-weather elevator test data for the Winter Olympics originated from this very technology.

Inside the intelligent connected vehicle test zone, visitors lined up for a "virtual crash test." Seated in a cockpit, they watched a 5G-linked avoidance algorithm steer a sharp turn to safety, drawing gasps and applause. In the north corner of the exhibition hall, CAERI's Kairui robotics team ran an infrared 3D motion-analysis system to trace robot trajectories, speeds and data in real time.

"Inspection and testing are evolving from quality gatekeepers to innovation accelerators," said a spokesperson for the Chongqing Administration for Market Regulation. To meet the needs of the "33618" modern manufacturing cluster system, the municipality is building a RMB100 billion-level inspection and testing industrial cluster that already hosts nationally renowned "Chongqing Testing" brands, pushing certification toward global recognition. Today, the technical services of Chongqing's "testing corps" extend from western China to the global stage.

(Photograph courtesy of the interviewee)

Source: New Chongqing - Chongqing Daily

渝公网安备 50010502003501号

渝公网安备 50010502003501号